Processing of Plastics

Many years experience at the domestic and foreign market. Innovative solutions, modern machine park.

Range of manufactured products:

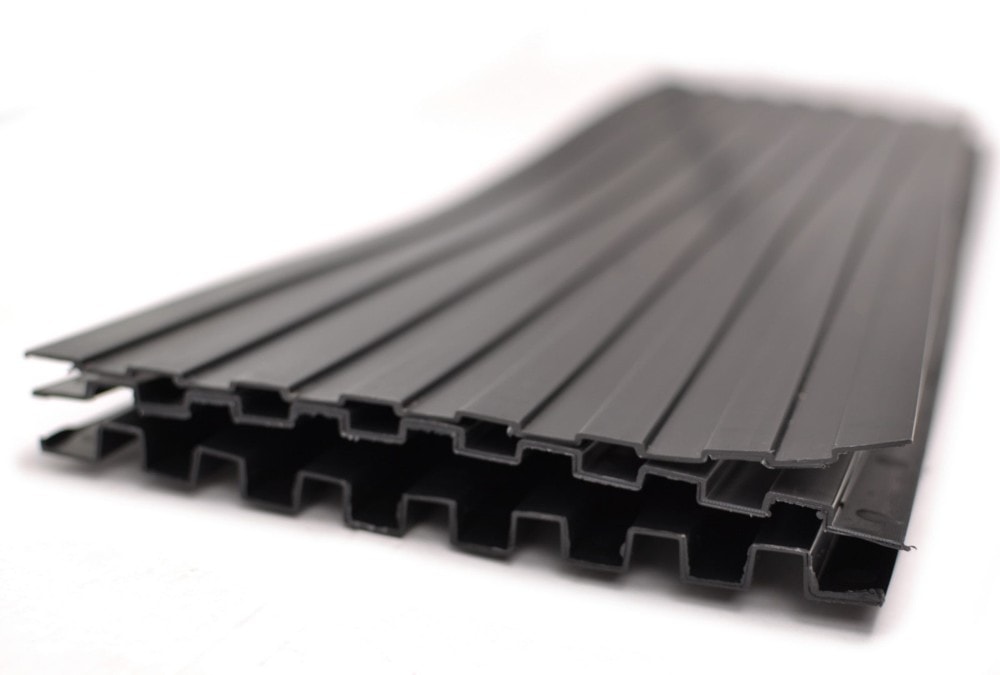

✔ Components for the production of batteries for motorization industry: boxes and lids

✔ Other assembly components: plugs, casings, rings, handles

✔ Indicators of oil level for combustion engines

✔ Components of filters for sewage plants

✔ Other products compliant to costumer specifications

✔ Other assembly components: plugs, casings, rings, handles

✔ Indicators of oil level for combustion engines

✔ Components of filters for sewage plants

✔ Other products compliant to costumer specifications

Technical equipment:

✔ Modern injection molding machine with a maximum clamping force of 800 tons with a 3-axis robots

✔ silos for the storage of raw materials

✔ The central feeding system for plastic granulate

✔ laboratory equipped with measuring and control equipment

The basic raw material is processed is polypropylene PP compound.

In addition there are also used other materials: PE, ABS, PA for processing.

✔ silos for the storage of raw materials

✔ The central feeding system for plastic granulate

✔ laboratory equipped with measuring and control equipment

The basic raw material is processed is polypropylene PP compound.

In addition there are also used other materials: PE, ABS, PA for processing.

Quality control:

Permanent control and monitoring of the quality of products supplied

✔ Determination of melt flow rate (MFR) acc. to EN ISO 1133

✔ Determination of Moisture

✔ Determination of solid material in the plastic acc. to ISO 3451-1

✔ Durability properties control of the plastic samples by stretching. EN ISO 527-1

Continuous process control and product

✔ 100% control of electrical resistance of the molding

✔ Electronic automatic recording of measurements

✔ controls the mechanical properties of moldings (test impact resistance and thermal stability)

✔ Cooperation with external laboratories and research units

✔ Determination of melt flow rate (MFR) acc. to EN ISO 1133

✔ Determination of Moisture

✔ Determination of solid material in the plastic acc. to ISO 3451-1

✔ Durability properties control of the plastic samples by stretching. EN ISO 527-1

Continuous process control and product

✔ 100% control of electrical resistance of the molding

✔ Electronic automatic recording of measurements

✔ controls the mechanical properties of moldings (test impact resistance and thermal stability)

✔ Cooperation with external laboratories and research units

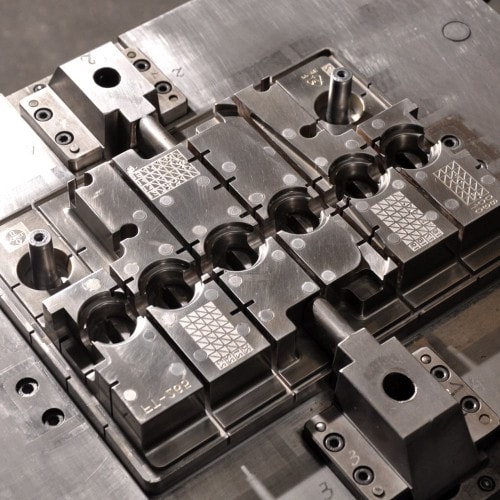

Cooperation with the Tooling Department

Plastics processing department close works with toolmakers in the execution, modification, maintenance of injection molds and production equipment.

Read more in tool department section

Read more in tool department section

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)